Water Vapour Cryopump Solutions

The MegaCold Water Vapour Cryopump is the most cost effective addition to an existing vacuum system or as part of a vacuum pumping solution for new systems. It can dramatically reduce pump down times and significantly improve product quality and throughput. In production this means more cycles per day. Typically 50- 100% throughput improvements are achievable. The MegaCold works on the principle of Meissner trapping. Water vapour is captured by condensing onto a cryogenically cooled surface (a cryocoil) that is placed inside the vacuum chamber so pumping is not limited by pumping ports.

The MegaCold is controlled by an industry standard PLC with a touchscreen local interface for ease of use and graphing of current or historic data. It has a full set of remote options. The equipment is available in a range of configurations including single & dual output cooling circuits giving independent control over a cryocoil and baffle.

Megatech has been involved in the vacuum industry for over 40 years. We have supplied equipment and offered service and support during this time gaining much experience and knowledge along the way. We offer a complete solution to your water vapour pumping needs. Our experienced team of sales and service engineers are always available to offer advice.

Megatech provide worldwide sales and support for the MegaCold series. Our facilities are in the UK and mainland Europe. We have designated service partners around the world to meet rapid service call-out requirements.

Selection and Application

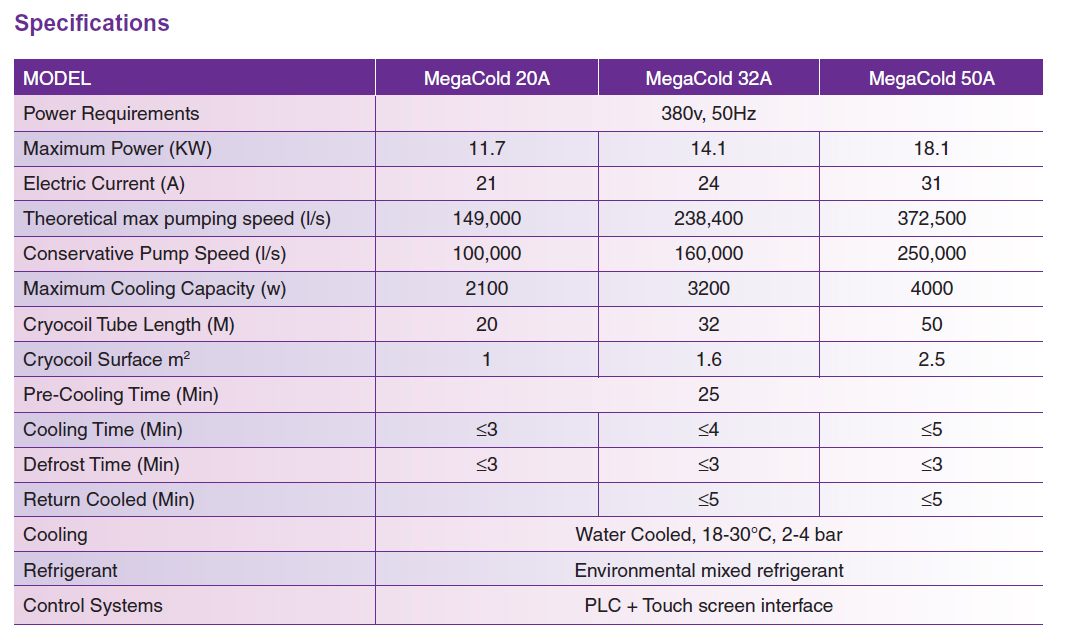

Selecting and sizing the appropriate model for the application is dependent on many variables. Based on our years of experience we have established some baseline principles to simplify this task. Typically, when adding water vapour pumping on an open load system, pump down times are reduced in the range 50-75%. To accomplish this we take existing Water Vapour Pumping speed of the pumping system (in chamber) and multiply by a minimum factor of 4. Taking this value we are able to determine the cryocoil surface area. Knowing the ultimate vacuum level of the process chamber we can look up the coil temperature required from the featured table. Now knowing the temperature required we can determine the cooling capacity required and select the appropriate model. Allowances may need to be made for any additional heat sources within the chamber or if the Cryopump is placed a significant distance from the vacuum chamber.

Key System Components

In addition to the MegaCold unit the following key components are also available and can be manufactured by Megatech to your specification if required:

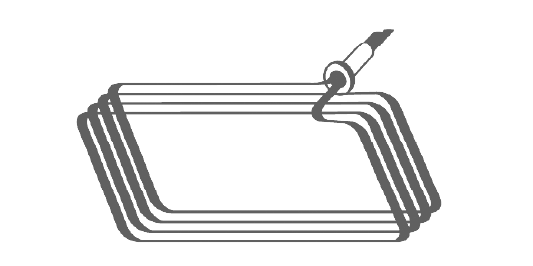

Cryocoil

The cryocoil will be designed to fit the specific vacuum chamber, based on information you supply, or you may choose to design and build your own cryocoil. Typical cryocoils have helical, spiral, serpentine or other simple shapes.

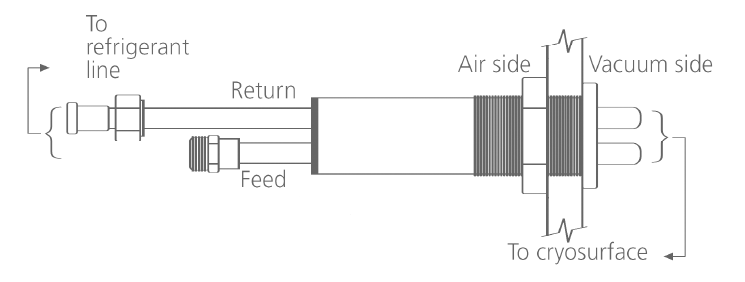

Feedthrough

The standard cryogenic feedthrough provides thermal isolation between the feed/return tubes and the O-ring seal. The dual pass feedthrough requires a two-inch diameter hole in the vacuum chamber.

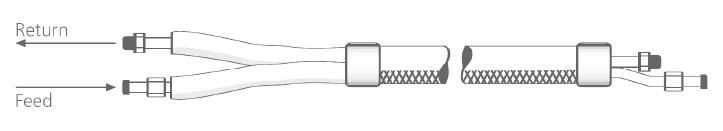

Refrigerant Line

A standard refrigerant line set consists of a copper feed and return line, each with stainless steel couplings on both ends for connection to the MegaCold unit and to the feedthrough. Optional vacuum insulated lines are available if required.

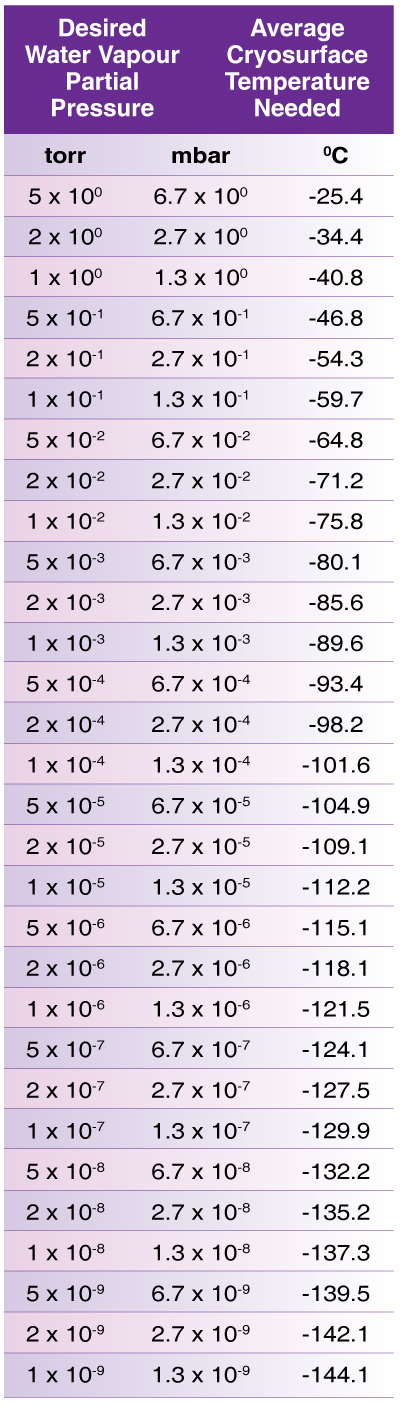

What’s the best temperature to trap water vapour effectively?

To find the cryosurface temperature that is best for your vacuum system, find the ultimate base pressure of your system listed below. Then follow across to the right column which shows the required cryosurface temperature. This temperature provides 90% water vapor trapping efficiency.

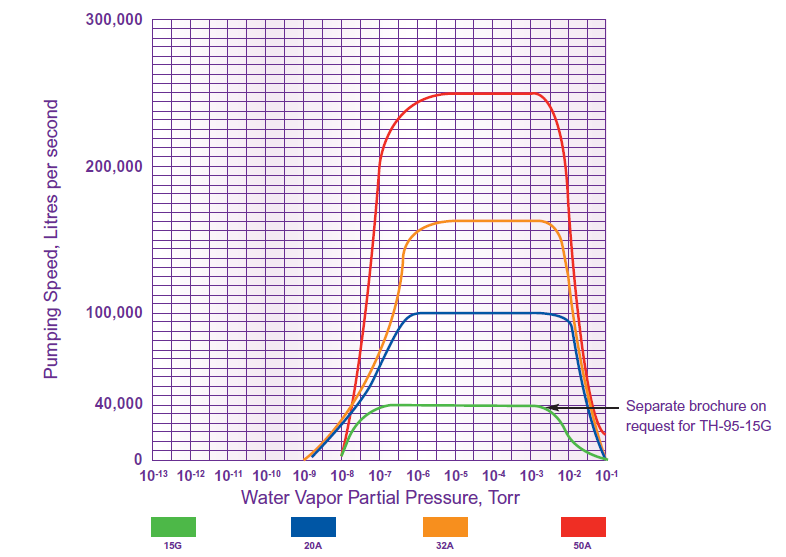

Comparison of Cryopumping Speed and Pressure - 50 Hz

NOTE: Based on performance at 50Hz

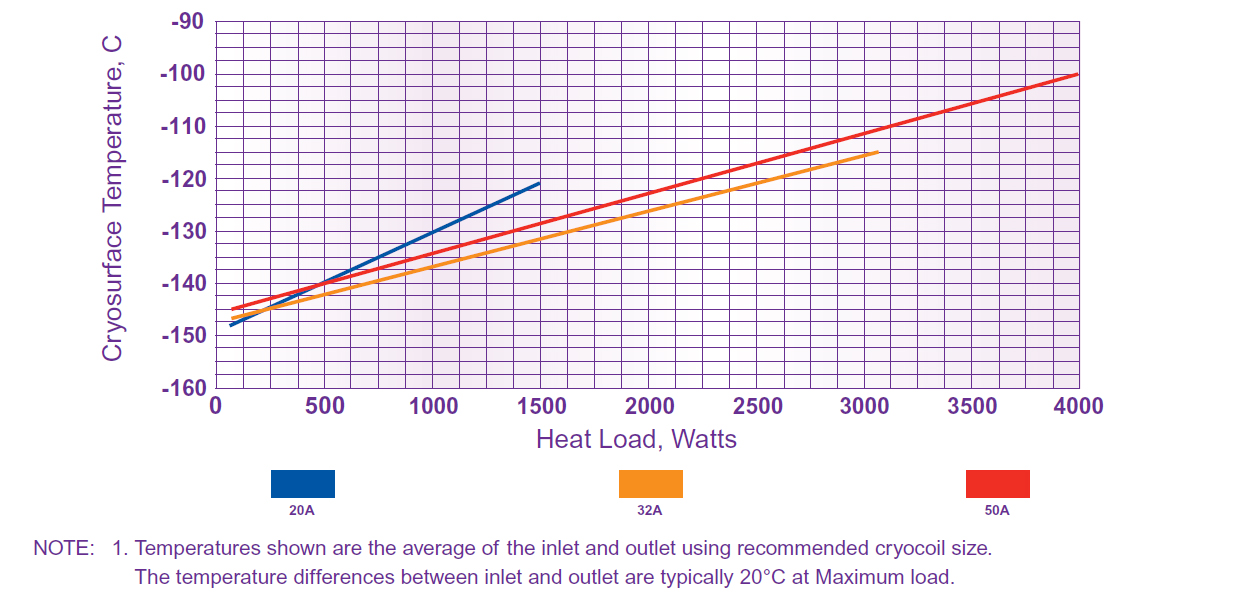

Comparison of Average Temperature (A) and Cryosurface Temperature vs. Heat Load (B) - 50 Hz

[vc_row 0=””][vc_column 0=””][vc_column_text 0=””]

Please click here to access Megacold Machine Catalogue.

[/vc_column_text][/vc_column][/vc_row]